As more States enter the later phases of reopening, many business owners are focused on disinfection protocols, new safety standards, and occupancy restrictions to prevent the spread of coronavirus. While these practices are essential for occupant safety, another silent killer should be on every building owner’s radar. Stark Tech’s building intelligence programs can help.

Legionaires’ Disease is spread by inhaling water droplets contaminated with Legionella pneumophilia bacteria. While rare, this bacterium may form in inactive buildings, such as schools, gyms, office buildings, and other buildings that were left abandoned for far longer than a week – the time frame for when Legionella risk begins to increase. Legionaires’ Disease presents similar to coronavirus as it causes severe pneumonia in those infected. However, the disease does not spread person to person. Rather large community outbreaks are caused through contaminated airborne water droplets, which can form in HVAC systems, gym showerheads, cooling towers, water taps, pools and water fountains.

The bacteria thrives in warm environments, feeding on pipework sludge and sediment. The Center for Disease Control states that intermittent use of buildings and equipment, paired with the interruption of regular cleaning regimens, increase the likelihood of water stagnation and in-turn the likelihood of a Legionella outbreak. Stark Tech’s building intelligence services can help prevent water stagnation and outbreaks that result from inactive buildings.

According the Chartered Institute of Environmental Health, effective water management programs in buildings, facilities and plants will eliminate any public threat to a Legionella outbreak.

Legionella bacteria thrive at temperatures between 68- and 122-degrees Fahrenheit. Building Controls & Automation play an important role in preventing this bacterial spread by setting water temperature outside of the range where the bacteria thrives.

A building is more likely to be safely reopened if the following measures are implemented:

Water Systems:

- Routinely purge stagnant lines. Stagnant water is conducive to Legionella growth and prevents the biocide from circulating throughout the system

- Consider contacting your local water utility to learn about any recent disruptions in the water supply. This could include working with the local water utility to ensure that standard checkpoints near the building or at the meter to the building have recently been checked. Request that disinfectant residual entering the building meets expected standards.

- Check water temperature and increase to above 150.8 degrees Farhenheit, if below thresholds (in addition the thermostatic mixing valve before the tap should reduce temperature to 109.4 degrees Fahrenheit to prevent scalding)

- Check water treatment chemical levels and chemical pumps daily. Legionella levels can skyrocket in a short time if a biocide drum is empty or a chemical pump is broken

- Control the buildup of dirt and debris. Clean basins and sumps as needed and the entire system twice a year. The cleaning alone has little effect on Legionella concentrations, but it is crucial for effective water treatment

- Implement a chemical or thermal disinfection of the water system

- Take microbiological samples for Legionella bacteria prior to re-opening

- Clean all decorative water features, such as fountains. Be sure to follow any recommended manufacturer guidelines for cleaning and that decorative water features are free of visible slime or biofilm

- Ensure safety equipment including fire sprinkler systems, eye wash stations, and safety showers are clean and well-maintained

HVAC & Cooling Systems:

- Treat cooling water for control of Legionella and other microbes. If the tower appears well-maintained, perform an online disinfection procedure

- Follow ASHRAE Guideline 12-2000 regarding cooling tower shutdown and startup for Building Water Systems =

- Install and maintain high efficiency drift eliminators to minimize the mist that escapes the tower

- Consider side stream filtration to reduce suspended solids and the demand on the biocide further. For most systems, filtering at 3% to 5% of the circulated water to 20 to 50 microns is sufficient

- For most cooling towers, daily checks to test for pH, total dissolved solids, and disinfectant levels (if applicable), in addition to total bacteria counts (TBC) or Adenosine Triphosphate (ATP) at least once a week to evaluate the water treatment—a significant rise indicates a problem.

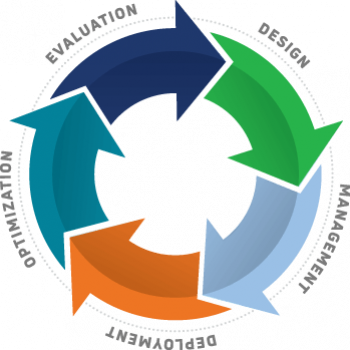

Stark Tech is prepared to help with strategic plans for reopening buildings, including preparing the building to prevent a Legionella outbreak. Together, with the appropriate measures in place, occupants can feel safe to return to work. Stark Tech Building Intelligence is available to address health and wellness concerns on a continual basis to ensure the health and safety of staff and visitors.

For more information call 716.693.4490. Stay healthy. Stay safe.