A disciplined approach to commissioning because systems are required to be fully-functioning and operating as designed from day one and throughout the system lifecycle to meet project requirements.

design process

Client alignment through entire engineering process to understand system requirements for design.

Project Commissioning

Process of planning, documenting, scheduling, testing, adjusting, verifying and operational training.

Autocommissioning

Automation software so all aspects of the system or systems operate in a persistently commissioned state.

Quality Control

Performance commissioning with functional testing of equipment on new construction and retrofit projects.

Building technologies require testing and documentation to confirm operation and performance of today’s smart building designs.

Stark Tech can provide you with the specific equipment required for safe learning environments but can work with you to integrate it into your existing building infrastructure.

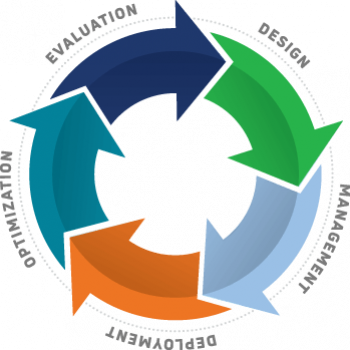

Commissioning is the quality assurance process that proves building and system performance meet specification requirements. This is a systematic process to ensure the building and operating systems are performing in accordance with design intent, the contract documents, and the owner’s operational needs.

Additionally, commissioning is critical for ensuring building designs have been successfully constructed and, at startup, are operating as intended. Dynamic commissioning goes a step further, and applies automation technology to persistently maintain systems at the operational intent throughout its lifecycle.

Stark Tech’s proprietary software applies predictive analytics and machine learning to provide prescriptive maintenance strategies to ensure constant commissioning at the system and building level.

Energy efficient buildings, especially LEED and WELL certified buildings, require advanced control settings to evaluate the efficiency of design and qualify that the volatile organic compounds (VOC) emission content meets certification requirements.

Finally, Stark Tech has proven success, providing commissioning services that have helped achieve up to 25% operational savings, 30% maintenance savings, and 40% energy savings.

Our turnkey services and engineering support capabilities can be provided separately or combined for an integrated solution that delivers the results needed to achieve your optimization goals and objectives.

Turnkey Project Management

End-to-End support from concept and design through project management & commissioning to scope and budget.

Building Technologies

Master Systems Integration with live monitoring & automated controls, actionable insights & optimization strategies.

BUILDING INTELLIGENCE

Command center live monitoring, strategic action and service that minimize operational disruptions and optimize performance.

Facilities Equipment

Engineered solutions for HVAC, critical power, thermal applications to control temperature, humidity & IAQ.

Parts & Service

Factory-trained & certified OEM service provider, including start-up, configuration & inspection qualification.

BATTERY ENERGY STORAGE

Battery energy storage systems and engineering support for large-scale deployments and microgrid applications.

Renewable Integrations

Clean-tech solutions, including solar development, energy master planning, consulting, and implementation.

RNG & Compression

High-quality skid systems with engineering for compressed air, liquid applications, landfill, biogas & wastewater.

Our clients recognize and value our distinctive and validated approach. No other organization matches our combination of building and energy systems expertise, analytics platform, engineering, & IT network professionals.

In a quick 16-week turnaround, Stark Tech was able to install dehumidifiers to maintain tight humidity control in order to achieve the cleanroom conditions needed to convert the 306,000 sq. ft. warehouse into a mass production site.

In a green architecture design, Stark Tech incorporated a vegetated lower roof and photovoltaic collector on the upper roof with integrated temperature and lighting controls to maintain parameters that save energy and cost.

The project is a 350 scfm waste water treatment plant. “The ability to capture biogas from our sewage (and transform it into RNG) is the type of innovative project that will help us reach our renewable energy goals sooner rather than later.”

Connect with a Stark Rep Today

Copyright © 2024 | All Rights Reserved

CONNECT WITH A STARK REP TODAY

When you speak to a representative about sustainable initiatives for energy efficiency, you gain access to tailored expert knowledge and guidance. You’ll quickly discover innovative technologies and cost-saving measures that empower you to make informed choices.